Various failures of the ultrasonic probe may result in inaccurate imaging or unusability. These failures range from acoustic lens bubbling to array and housing failures and can have a significant impact on the quality of the ultrasound image. Our team can provide you with ultrasound probe repair services, probe accessories customization (including arrays, probe housings, cable assemblies, oil bladders, sheaths, etc.) and endoscope repair services.

One of the common faults of ultrasound probes is the failure of the acoustic lens. Bubbling in the acoustic lens will cause local black shadows on the ultrasound image, but the black shadow may disappear when the dark shadow area is pressed appropriately; damage to the acoustic lens will cause the coupling agent to penetrate into the array. crystal layer, causing the crystal to be corroded.

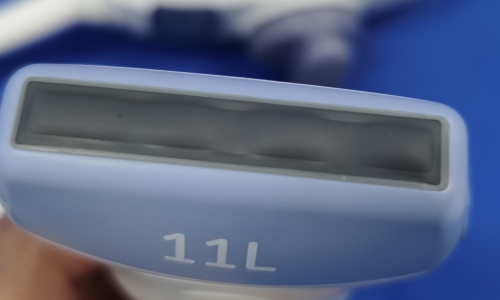

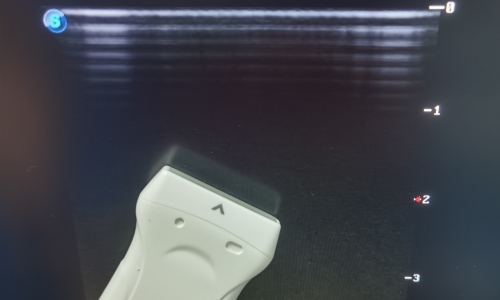

In addition to acoustic lens failure, array failure is another issue that can affect ultrasound probe performance. When the array (crystal) is damaged, dark channels, blood flow, etc. may appear, affecting the overall image quality. If the crystal damage is concentrated or in the middle, it will obviously affect the normal use of the probe.

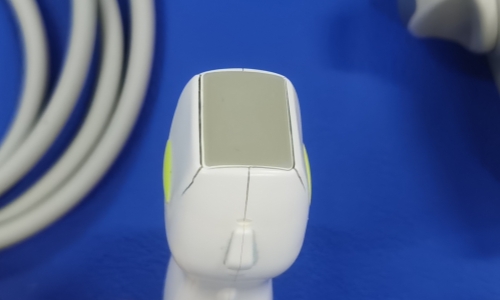

In addition, the rupture of the shell will cause the coupling agent to penetrate into the probe. If not solved in time, it will cause oxidation and corrosion of the array (crystal).

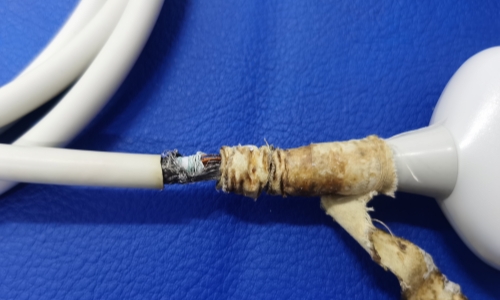

The importance of cable protective layer sheath: If the sheath is damaged and not repaired in time, it may damage the cable and further affect the performance of the ultrasonic probe.

Circuit failure is also another significant issue, as it can cause dark channels, interference, and ghosting in the probe. Cables serve as the carrier to connect to the host system, and any failure of the cable will directly affect the imaging quality.

Additionally, circuit failures can cause the probe to report errors, spark, fail to recognize, and create ghost images in the image, further compromising the accuracy of ultrasound imaging.

Oil bladder failure: This may cause oil leakage and cause some black shadows to appear in the image. When the oil bladder is damaged, it should be repaired in time.

The final three-dimensional/four-dimensional fault: manifested as three-dimensional/four-dimensional failure (no image) and motor failure.

Overall, it is important to maintain and inspect ultrasound probes regularly so that any potential failures can be identified and resolved before they affect imaging quality. By understanding and addressing these potential failures, medical professionals can ensure the accuracy and reliability of ultrasound imaging used for diagnostic purposes.

Our contact number: +86 13027992113

Our email: 3512673782@qq.com

Our website: https://www.genosound.com/

Post time: Dec-13-2023